FineCut 14T / BST 12T / AST 20T

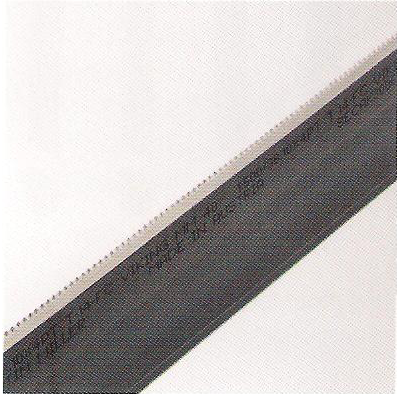

FineCut 14T

| Execution | MM 40 | MM 44 | HP 44 |

| Hardness | ~380 HV | ~ 430 HV | ~430 HV |

| Bevel | T (Asymmetric) | ||

| Height | 34.80 - 50.80mm 0.937" - 2.000" | ||

It performs with minimal penetration on many different types of materials.

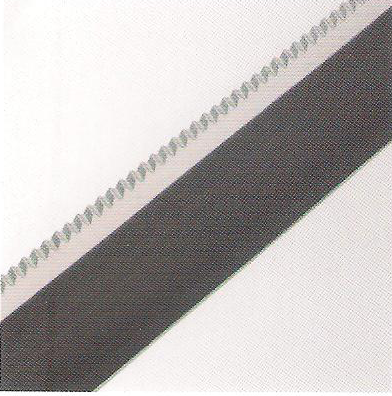

BST 12T

| Execution | MM 34 | HP 34 | |

| Hardness | ~340 HV | ~340 HV | |

| Bevel | B (Side bevel) | ||

| Thickness | 4 pt / 1.42 mm | ||

| Height | 23.80 - 26.40 mm 0.937" - 1.039" | ||

12T was the starting point in rotary diecutting and has moved more and more from side bevel to center bevel. But side bevel still has some limited uses today.

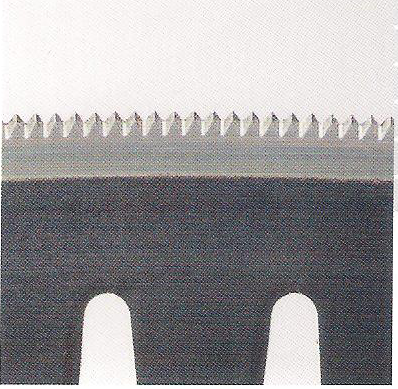

AST 20T

| Execution | MM 34 | HP 34 | |

| Hardness | ~340 HV | ~340 HV | |

| Thickness | 4 pt / 1.42 mm | ||

| Height | 23.80 - 26.40 mm 0.937" - 1.039" | ||

This rule is appropriate when a clean edge appearance is required.

Back Executions

| SNN | SN | CUR | CNN |

| straight, no notches | straight, with notches | curved, with notches | curved, no notches |

| Notch depth t = 12.7 mm - conical (CON), t = 12.2 mm - parallel (PAR) |

| Notch distance T = 12.7 mm - conical (CON), T = 10 mm - parallel (PAR) |

| Other notch depths on request. |

Form of Delivery

| SNN | SN | CUR | CNN | |||

| in lengths | rule length | 1 m/762 mm (30'') | 1 m/762 mm (30'') | - | - | |

| in coils | coil length | 3 pt - 70 m * 4 pt - 50 m | 3 pt - 70 m * 4 pt - 50 m | 4 pt - 30.5 m | 4 pt - 30.5 m | |

| standard inner coil-Ø | 400 mm | 400 mm | 487 mm | 487 mm | ||

| (others on request) | (177 mm - 664 mm) | (270 mm - 664 mm) | ||||

| winding direction | RU: coil end on top left hand "∂" | N: counter-clockwise | ||||

| (view on bevel) | R: coil end on top right hand "6" | U: clockwise | ||||

| Due to our unique production method we achieve extremely small curving diameters: CUR = 177 mm, CNN = 270 mm | ||||||