Edge-hardened Cutting Rules

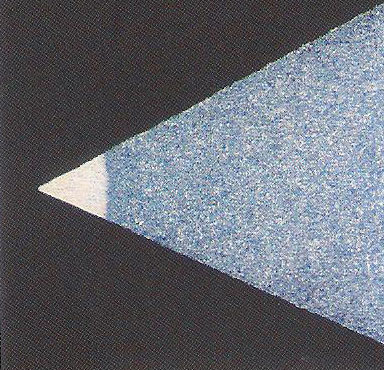

HP plasma hardened

HP – Properties

- Edge-hardened by special plasma hardening process

- Highest possible lifetime of the die, due to high cutting edge hardness of ~ 700 HV (~ 60 HRC)

- HP is unique to Martin Miller cutting rules

HP – Applicaton

- For high to extremely high production runs/number of cuts

- Dust reduction in the cutting process

- Optimized for tight bends

Special execution

Vikingflex HF cutting rules on request.

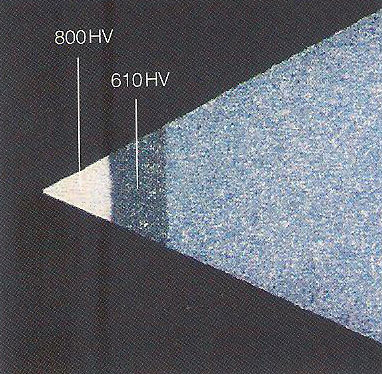

HP+

HP+ – Properties

- Unique dual edge hardening process

- Multi layer combines HF and Plasma hardening technology with ~800 HV (~64 HRC) on tip and deep edge hardened zone

- Extended lifetime of cutting tool

HP+ – Application

- Processing on automatic bending machines still possible

- Carton, duplex board, rigid and thick materials, gaskets, stiff plastic, compounds

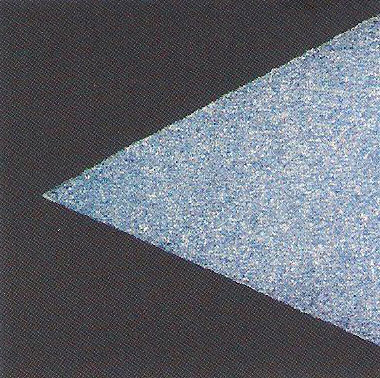

MM trough hardened

MM – Properties

- The same hardness of cutting edge and body

- Good bendability due to soft and ductile surface layer

MM – Application

- Small to medium size runes/number of cuts

- Good bending properties

- All purpose rule (carton, corrugated)